By William C. Bailey, on November 30, 2023, The NEBB Professional – Q3 2023 Edition

Beginning with a phone call from a nearby hospital in the Nashville area, our construction division was called to solve a problem. The facility manager of the hospital asked if we could investigate why the air handling unity (AHU) serving the maternity ward patient rooms and floor area was not maintaining space and humidity temperature set points during the mid-summer. The existing unit had served the space for multiple years and had never experienced any issues in the past.

This system was installed by a reputable mechanical contractor who had been doing work for years for the hospital. The installation consisted of a built-up AHU with a supply-fan and cooling coil section, mixed air plenum section (outdoor air (OA) damper intake and return damper)), pressure relief damper, and a return fan. Both supply and return fan speeds were controlled by VFDs through an electronic building automation system (BAS). There was nothing special about the system. All VAVs and CAVs were primary air with hot water reheat for zone and humidity control. The return duct was ducted into the plenum at the top with the OA intake coming through a wall cavity to the mixing plenum.

Upon arriving on site, I sat down with the facility manager and asked questions to get a better understanding of what was taking place. He mentioned that as the day went on, the system graphics would show the system could not keep up (usually mid-afternoon) and the unit would struggle to maintain the area’s comfort levels.

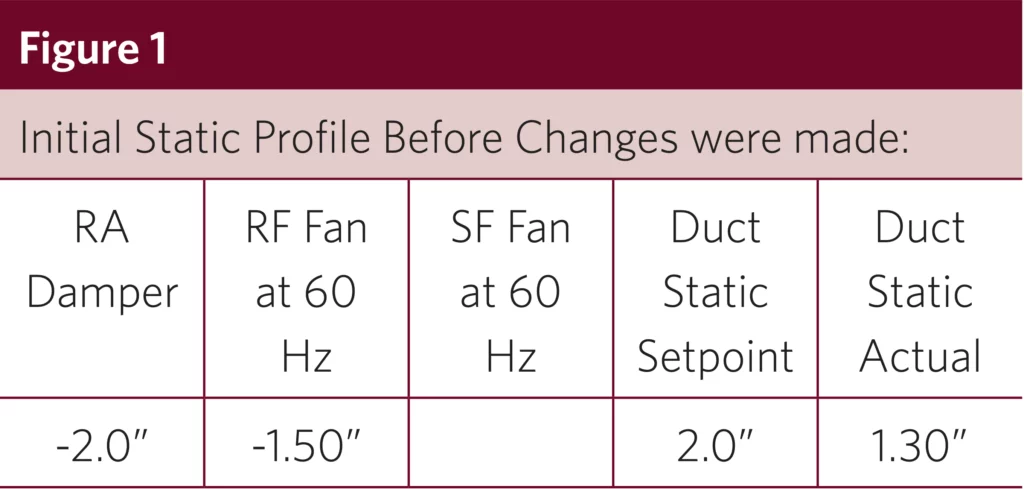

When reviewing the BAS, I observed the supply fan was not achieving the discharge static set point and was operating at 60 Hz. The static set point was 2.0” wc. (500 Pa), and the fan was delivering 1.3” wc. (325 Pa) to the system. Several VAVs were 100 percent open, and the maximum CFM values were not being achieved. I also observed that the discharge air temperature was not being achieved. The DAT set point was 52oF (11oC) and the actual DAT was 61oF (16oC).

At this time, I decided to go and review the equipment to try and determine what was taking place. My first thought was that we were experiencing issues with OA and return air dampers, causing increased load to the chilled water coil since the area was experiencing warm and humid conditions. As I tried to open the door to the mixed air plenum, it would not open. It appeared the suction static was high to the mixed plenum section. At this point, I decided to take some static pressure measurements to see where we stood. As you can see in Figure 1 below, I experienced very abnormal readings for a typical built-up HVAC system in the mixed plenum section of the unit.

While doing more investigating, it was strange to see that the mixed plenum was so high. I thought maybe the fire/smoke damper was partially closed, causing the high suction static. After all, the unit had been in operation for multiple years with no real issues.

After doing the initial checks and finding the dampers were open as required, I decided to go back and visit the return fan to see what was taking place. It appeared as if the return fan was not operating at all. The VFD showed it was operating at 60 Hz. So, I decided to review the rotation of the return fan. I observed the return fan was rotating backwards.

The facility engineer approved shutting down the system to swap the leads on the incoming power for the return fan VFD. The return fan had a bypass for the VFD as well. The facility engineer reached out to area nurses and administration personnel to get approval for the brief shutdown.

Meanwhile, I asked questions regarding how the system functioned correctly for multiple years and now all of a sudden had issues. I learned that a wall where the VFDs were located had to be relocated and was moved a month prior. At that time, the electrical contractor chose to disconnect and relocate the VFDs without the assistance of the mechanical contractor.

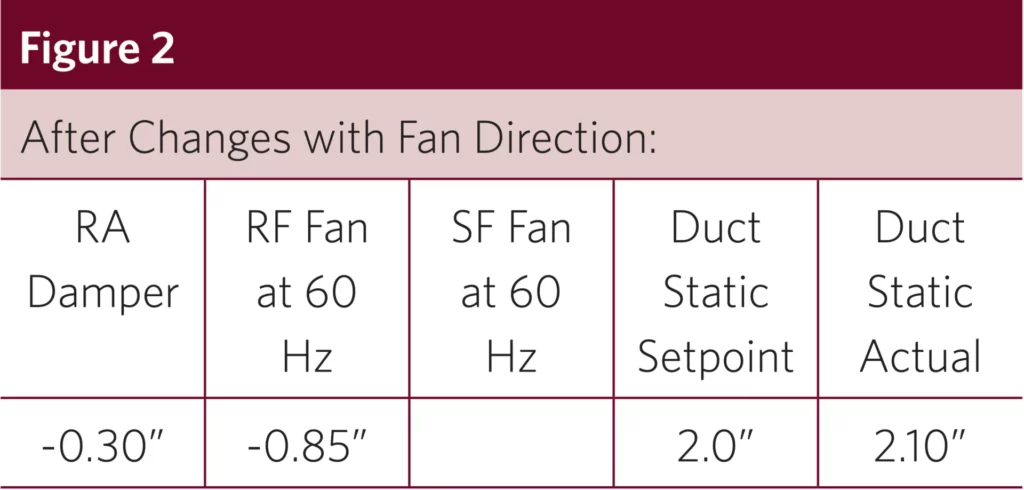

We put the breaker in the off state, checked that we had no live voltage, and switched the wiring on two of the three phases to get the incoming power phased correctly. We also confirmed the bypass rotation was correct, as well. After allowing the VAVs and CAVs to settle out and the air handler to obtain the set point with discharge air and static values, I measured the static readings once again to see how the system was performing. The discharge air temperature was at 52oF (11oC) and modulating the chilled water valve. With the RA fan not performing and running backward prior, there was a substantial increase in minimum outside air due to the high suction static to the mixed air section, causing the overall system to struggle. Below, Figure 2 shows readings as observed when the system settled out.

Often, we can look at things in many ways and have many different thoughts or concerns for what is happening with a system when troubleshooting. The key thing is to not forget the common things, which could be the simplest of issues. As we grow and learn systems and how they work, the training and education we pick up and try to pass onto others is essential. This is why NEBB helps to promote CTs and CPs, making us experts in the field of HVAC. Once again, this experience made me feel blessed that I have been with such a great group of people and organization.